Seit über 70 Jahren stellen wir Sonderkrane in Saalfeld her. Durch unsere langjährige Erfahrung im Kranbau können wir die unterschiedlichsten und individuellsten Kundenwünsche berücksichtigen und umsetzen. Der spannende Weg zur perfekten Transportlösung beginnt in der Entwicklungsphase, in der unsere Motivation, Erfahrung und Innovationskraft besonders gefragt sind. Die Vielfalt unserer bisher ausgelieferten, kundenspezifischen Krananlagen unterstreicht dies eindrucksvoll.

Neben Kranen haben wir uns erfolgreich als Experten für sicherheitsrelevante Bauteile und Komponenten im Bereich Fördertechnik positioniert.

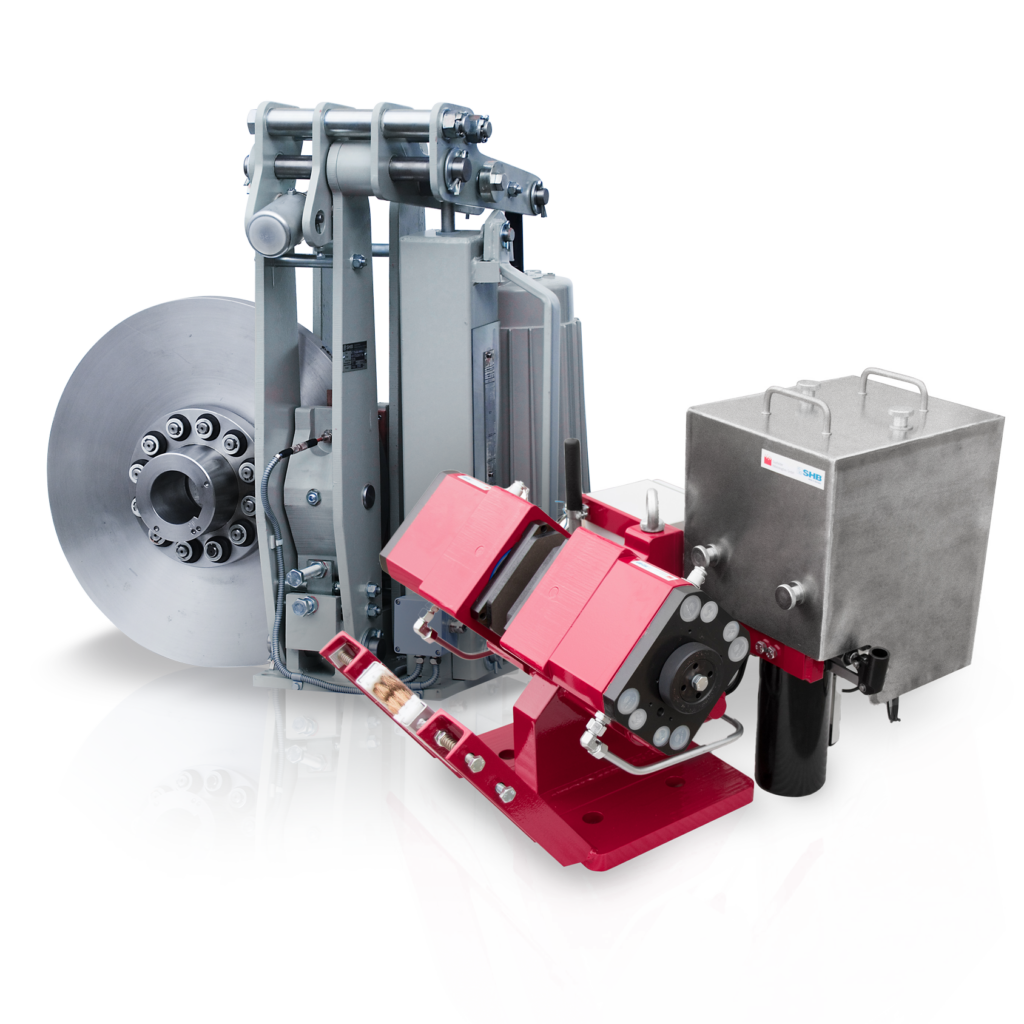

Unser Produktprogramm in der Fördertechnik beinhaltet Trommelbremsen, Scheibenbremsen, Hydraulikpuffer, Kupplungen, Bremsscheiben, Bremstrommeln, Laufräder, Laufradsätze und Seiltrommeln.

Wir bieten eine große Auswahl an bahntechnischen Komponenten im Bereich von Zug- und Stoßeinrichtungen. In enger Zusammenarbeit mit der ETQ Eisenbahntechnische Anwendungen GmbH arbeiten wir in den Bereichen Forschung, Entwicklung, Konstruktion und Erprobung, um innovative Lösungen für den Bahnverkehr anzubieten.

Unser vielfältiges Fertigungsprogramm beinhaltet verschiedene Typen von Lokomotiv-Zugeinrichtungen mit Zugkräften von 1,0 MN und 1,5 MN. Des Weiteren liefern wir Hydraulik-Kombistoßdämpfer sowie komplette Puffersysteme der Kategorie C und L nach EN 15551.

Kundenzufriedenheit ist für uns das oberste Gebot. Unser umfangreiches Angebot im Bereich Kranservice deckt neben dem regulären Service auch Wartungs-, Reparatur- und Umbauarbeiten ab sowie alle vorgeschriebenen Sicherheitsprüfungen im Rahmen der UVV-Prüfung.

Möchten Sie vielseitige und abwechslungsreiche Tätigkeitsfelder in einem international tätigen Unternehmen mit hervorragendem Arbeitsklima kennenlernen? Dann sind Sie bei uns genau richtig.

Der respektvolle Umgang miteinander steht bei uns im Vordergrund und Ihr Wohlbefinden ist uns wichtig. Bei der SHB bieten wir jedem Mitarbeiter individuelle Weiterbildungsmöglichkeiten. Wir suchen neue Kollegen (m/w/d) zur Unterstützung unseres Teams, ob als Auszubildende/r, in der Fertigung, in der Verwaltung oder im technischen Büro.

Sind Sie bereit, gemeinsam mit uns neuen Herausforderungen zu begegnen? Dann freuen wir uns auf Ihre Bewerbung über unser Online-Portal!

SHB Hebezeugbau GmbH blickt auf mehr als 70 Jahre Erfolgsgeschichte zurück, in der Tradition und umfangreiche Erfahrung eng miteinander verbunden sind. Unsere Kombination aus modernem Maschinenbau, innovativer Steuerungstechnik und individuellen Stahlbaulösungen setzt Maßstäbe in der heutigen Fördertechnik. Seit 2018 ist SHB Teil der Scheffer Gruppe.